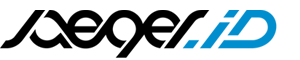

3D CAD Design and Surfacing

Modeling of 3D-NURBS Surfaces and Solids

In addition to the constructive implementation of its own design drafts into designs suitable for production, Jaeger.ID also offers the development of high-quality CAD data sets as an external service provider.

Areas of application

One strength is the rapid implementation of design constructions that can be used as a direct basis for rapid prototyping processes (3D printing, laser sintering, vacuum casting). This is due to the day-to-day business of design practice, which requires fast interim results without the need for production-ready elaboration. These are usually preliminary models for the visual assessment of designs and functional prototypes.

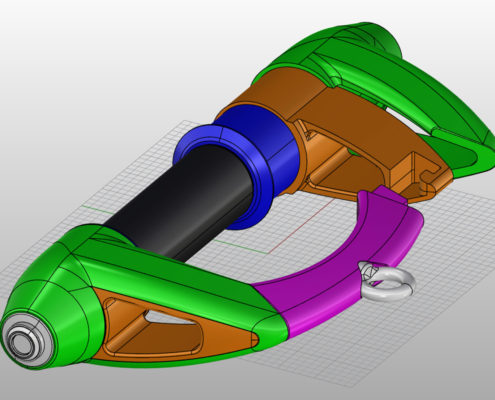

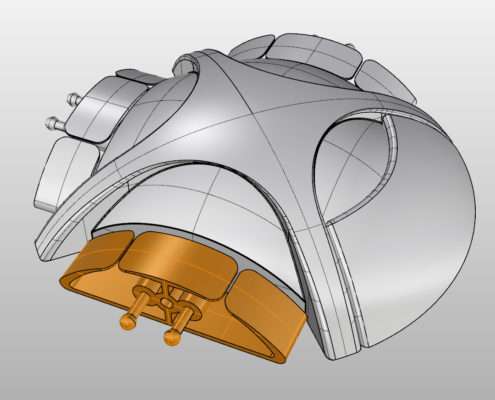

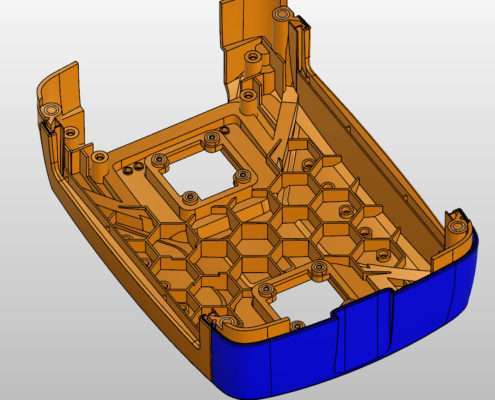

In addition to the designs for rapid prototyping, final elaborations for series production are implemented in plastic and metal. These are, for example, designs suitable for injection molding, taking into account the required technical parameters and quality features, or CAD data for GRP laminate moulds that can be produced using CNC milling.

Precision and quality standards

The modeling of design-relevant organic free-form surfaces is often not one of the core competencies of design offices working in the field of classic engineering. Jaeger.ID supports them in these areas with the appropriate know-how and tools, e.g. Rhino3D.

Special tools are used for the modeling of design surfaces, which enable the reliable implementation of high-quality surface structures. The generated data sets are characterized by maximum precision and optimal surface description. A particular focus when creating curvature-continuous Class A surfaces is that only as many support curves are generated for the surface description as are necessary to clearly define the geometry. Too many control points would mean a loss of model quality, which must be avoided at all costs when high end product surfaces are to be achieved.

Data exchange and formats

The industry standards STEP and IGES are the usual way in which design data is exchanged with customers and service providers. This enables loss-free import into all common CAD platforms such as Catia, Solid Works, Inventor and other established CAD systems.

The STL format is used to transfer post-processed 3D scans or other polygon-based data sets that are suitable for rapid prototyping processes.